The FCLF100 Limefire header offers the classic lakes style that looks just right on many fenderless street rods; whether building for that nostalgic look or an ultra-modern design. The FCLF100 fits Ford 351C, 351M, and 400 engines.

INSTALL NOTES:

- The FCLF100 header features flanges that accommodate 4V cylinder heads. If using 2V cylinder heads, our copper adapter plates, part #2BBLFC are required.

NOTE: Images provided show the small block Chevy and other Limefire applications.

NOTES:

- Turnout Tip, Finned Block Off Plate, and other adapters are sold separately

- On engines making decent horsepower or vehicles doing considerable highway driving, adding PowerCaps to the Limefire is recommended! Please review the “Why use PowerCaps?” tab for additional information.

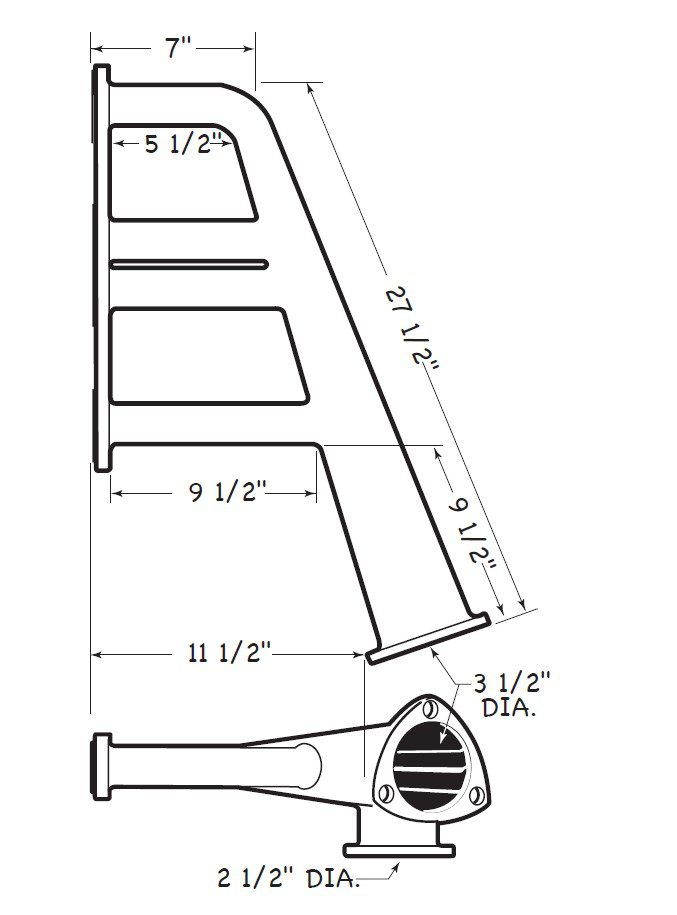

SPECIFICATIONS:

Engine: Ford 351C, 351m, and 400 V8

Primary Tube Diameter: 1-7/8″

Collector Diameter: 3½”

FEATURES:

- 16-Gauge Primary and Collector Tube Thickness

- 3/8″ Thick Flange

- Patented Flange Design Requires NO Gaskets

- Tightest Fitting Header Available Anywhere!

- Made in the USA

INCLUDES:

- Header Bolt Set

- Standard block off plate

FINISH:

Our Ceramic Coating is recommended for every vehicle application and is the default finish selection choice above. To meet high standards of quality, We apply a multi-layer inside and outside aluminized ceramic coating in-house and then polish the coating to a high luster. This aerospace and military-grade technology adds excellent protection to your headers while offering the benefit of thermal control in your engine bay. It also improves cylinder scavenging of exhaust gases and increases the longevity of your header investment.

Ford 4V vs 2V Heads

4V vs 2V Ford Cylinder Heads:

Sanderson headers for the Ford 351C, 351M, and 400 engines feature flanges for the larger port four-barrel (4V) cylinder heads. If using two-barrel (2V) cylinder heads, Sanderson part #2BBLFC copper adapter plates are required to ensure proper sealing.

When installing Sanderson headers with the 2BBLFC adapters, we recommended this installation procedure:

- Follow the standard installation instructions on our website that describe a thin “smear” of silicone gasket maker around the exhaust ports on the header flange. This will contact the adapter plate.

- Then, also apply a thin smear of silicone gasket maker on the opposite side of the adapter plate that will contact the cylinder head.

- Let the silicone fully dry overnight.

- Install the headers and the adapter plates onto the cylinder heads.

- Run the engine long enough to reach normal operating temperature for a few minutes.

- Let the engine cool and re-tighten the header bolts.

Why Use PowerCaps?

For those looking at the Sanderson Lakes-style Limefire and Jayster outside chassis headers for their street rod, here is a tech tip that might save some grief, frustration, and possible damage to the headers!

For those looking at the Sanderson Lakes-style Limefire and Jayster outside chassis headers for their street rod, here is a tech tip that might save some grief, frustration, and possible damage to the headers!

You may already know that the Sanderson lakes-style headers are available with or without connections for an under-chassis exhaust system. The ability to have a throaty open exhaust or a quiet and capped lakes-style header using an under-chassis system has been something Sanderson has offered since the original design.

We have found that on stock or mild street rod engines, there is not much of an issue if following the normal installation instructions. However, on applications making decent horsepower, it is possible to damage the header or header coating near the end of the collector where the under-chassis adapter connection is located. The cause of this problem is the turbulence created by the limited distance of dead space just after the under-chassis connection and the end cap on the header (when the header is capped and exhaust gasses are being routed through an under-chassis exhaust system). The turbulence in this area causes the EGT’s (Exhaust Gas Temperatures) to rise dramatically, and in certain applications, this could cause the temperatures to exceed the thermal capacity of the header coating—causing finish damage and discoloration. The problem only seems to occur on high-power engines and engines that are regularly operating at higher RPMs—for example, considerable highway driving on lower-geared vehicles.

The solution is relatively simple but adds cost to the header purchase. Sanderson designed a component called the “PowerCap” to solve this issue. The PowerCap slides into the collector tube and provides a smooth redirection of exhaust gas flow from the collector tube into the under-chassis exhaust tubing. The PowerCap bolts securely into your header using the end cap flange, thereby removing the turbulence area in the collector horn. Another benefit of using the PowerCaps is improved horsepower by improving airflow into the under-chassis exhaust. Although the PowerCaps are recommended for higher horsepower applications, they also benefit all applications using the under-chassis exhaust connection.

PowerCaps capture hidden horsepower on applications using under-chassis exhaust connections. Under-chassis adapters allow you to run a quieter under-chassis exhaust system, and adding the PowerCaps increases power and extends the life of your headers.

For those looking at the Sanderson Lakes-style Limefire and Jayster outside chassis headers for their street rod, here is a tech tip that might save some grief, frustration, and possible damage to the headers!

For those looking at the Sanderson Lakes-style Limefire and Jayster outside chassis headers for their street rod, here is a tech tip that might save some grief, frustration, and possible damage to the headers! Limited 5-Year General Warranty

Limited 5-Year General Warranty

Reviews

There are no reviews yet.