These are the real deal! Sanderson Zoomie headers feature the patented leak-free flange and include bolt-in baffles that knock the sound level down just enough for street use. If the classic dragster look is desired, these headers provide the look, Sanderson quality, and powerful sound for your vehicle.

NOTES:

- Please review the Baffle installation Instructions information tab

- Available with either standard rectangular port or square port flanges. Please review the “SB Ford Flanges” information tab.

- Images may include Zoomie headers for other engine applications

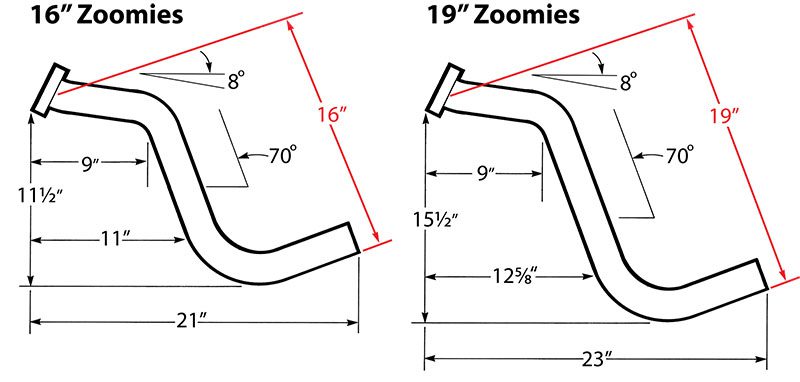

SPECIFICATIONS:

Engine: Small Block Ford 260-302, 351W V8

Primary Tube Diameter: 1-7/8″

FEATURES:

- 16-Gauge Primary and Collector Tube Thickness

- 3/8″ Thick Flange

- Patented Flange Design Requires NO Gaskets

- Tightest Fitting Header Available Anywhere!

- Made in the USA

INCLUDES:

- Header Bolt Set

- (8) Baffle Inserts

OPTIONS:

Sanderson’s Ceramic Coating is recommended for every vehicle application and is the default finish selection choice above. To meet high standards of quality, Sanderson applies a multi-layer inside and outside aluminized ceramic coating in-house and then polishes the coating to a high luster. This aerospace and military-grade technology adds excellent protection to your headers while offering the benefit of thermal control in your engine bay. It also improves cylinder scavenging of exhaust gases and increases the longevity of your header investment.

SB Ford Flanges

IMPORTANT UPDATE: Our small block Ford header flange has been redesigned to accommodate both standard rectangular and square exhaust port designs. This new flange is compatible with 2.0″ mounting bolt spacing

We are keeping the content below for informational purposes.

We offer two primary header flange styles for small block Ford engines. The standard rectangular port flange and a square port flange with 2.0″ bolt spacing. Factory OE Ford heads use a 2.0″ bolt spacing. Some aftermarket small block Ford cylinder heads include both the 2.0″ and 3.0″ bolt spacing Roush heads (SB427 for example) only use the 3.0″ bolt spacing.

The 3.0″ bolt spacing is a problem for thick-flange header sets because it makes installing the spark plugs virtually impossible, as shown in the images below. Only header sets built with thin 1/4″ – 3/16″ flanges are compatible with the 3.0″ bolt spacing.

Many aftermarket cylinder head manufacturers now use the square port shape on their products. However, that does not mean the square flange is required. The importance here is to ensure the header flange properly seals to the cylinder head. In most cases, the standard rectangular shape works perfectly, but on other heads, the square port flange is necessary. It is the customer’s responsibility to decide the correct flange for their application.

NOTE: Extra charges are incurred for headers ordered with the square port flange due to the additional manufacturing time required when building headers with the square port flange.

Below are two images showing the differences between the rectangular vs. square flange styles. The square flange shown utilizes the 2.0″: bolt spacing. Please use these images and the provided dimensions to ensure the proper flange is selected for your new Sanderson Headers from the drop-down menu on the product details.

Baffle Installation

Zoomie and Chopster Header Baffle Inserts:

Sanderson does NOT provide mounting holes for mounting the muffler baffle inserts due to possible liability issues. Safe installation and proper securing of the insert are the responsibility of the customer or installer.

Baffle Installation Procedure:

- First, make sure the inserts are the correct size for the application. Sanderson’s 1.875″ (1-7/8″) inserts are for small block engine applications, and the 2.250″ (2-1/4″) inserts are for big block engine applications.

- For NEW installations – Notice that one end of each Sanderson muffler insert is partly closed off with a welded washer.

- Use a tape measure to determine the depth of the insert from the end of the tube. Use that measurement to mark the inside of the header tube. The insert depth should be held up slightly from the short-side radius at the lower bend and not bottom out (see image below). Measure the insert depth for every tube.

- Insert the muffler into one of the pipes of the header with the partially closed-off end first. DO NOT FORCE. The insert should be snug, but not too tight.

- There are various methods to secure the insert. Either drill a hole slightly in front of the insert and install a stove bolt and locknut (or use red Loctite); or drill and tap directly into the baffle ring, using a properly sized bolt with a small amount of red Loctite on the bolt threads

- NOTE: Some customers have used sheet metal or self-drilling/tapping screws to hold the mufflers in place, but such screws tend to vibrate loose.

- When the mufflers are securely fitted in all eight pipes, the headers are ready to install on the engine.

Limited 5-Year General Warranty

Limited 5-Year General Warranty

Reviews

There are no reviews yet.